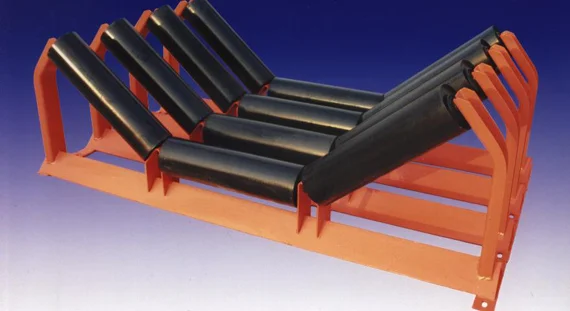

Plastic UHMWPE Conveyor Roller — High-Performance Solution for Bulk Material Handling

In the most demanding bulk material handling applications—such as mining, cement, chemical processing, and port terminals—durability, corrosion resistance, and low maintenance are critical. Our Plastic UHMWPE Conveyor Rollers are engineered to deliver superior performance in harsh operating environments, outperforming traditional steel rollers in key areas.

Character of the Plastic Uhmwpe Conveyor Roller

1. Non-Toxic and smell

2. Low coefficient of friction

3. Corrosion resistant

4. Self-lubricating

5. Wear Resistant

6. Abrasion and impact resistant

7. Anti-Weather and Anti-Aging

Application of the Plastic Uhmwpe Conveyor Roller

The Plastic Uhmwpe Standard Belt Conveyor Roller is widely used in the original dock transporting places where dust is bigger and the environment has high corrosive, such as mining, power, steel, Stone materials factory, cement and coking plant ,Coal washing factory, Salt plant, Alkali plant, Fertilizer factory, dock and so on.

1. Ultra-High Molecular Weight Polyethylene (UHMWPE) Construction

-

Provides exceptional impact resistance and abrasion resistance, reducing wear from abrasive materials like coal, ore, or clinker.

-

Surface hardness ensures low friction, protecting conveyor belts and reducing power consumption.

2. Corrosion and Chemical Resistance

-

Unlike steel, UHMWPE rollers are immune to rust and corrosion, making them ideal for humid, acidic, or chemically aggressive environments.

3. Lightweight & Easy Installation

-

Up to 50% lighter

| Parameter of the Ultra high Molecular Weight Polyethylene | ||||

| No. | Item | Unit | Test Standard | Result |

| 1 | Density | g/cm3 | GB/T1033-1966 | 0.95-1 |

| 2 | Molding shrinkage % | ASTMD6474 | 1.0-1.5 | |

| 3 | Elongation at break | % | GB/T1040-1992 | 238 |

| 4 | Tensile strength | Mpa | GB/T1040-1992 | 45.3 |

| 5 | Ball indentation hardness test 30g | Mpa | DINISO 2039-1 | 38 |

| 6 | Rockwell hardness | R | ISO868 | 57 |

| 7 | bending strength | Mpa | GB/T9341-2000 | 23 |

| 8 | Compression strength | Mpa | GB/T1041-1992 | 24 |

| 9 | Static softening temp. | ENISO3146 | 132 | |

| 10 | Specific heat | KJ(Kg.K) | 2.05 | |

| 11 | Impact strength | KJ/M3 | D-256 | 100-160 |

| 12 | heat conductivity | %(m/m) | ISO11358 | 0.16-0.14 |

| 13 | sliding properties and friction coefficient | PLASTIC/STEEL(WET) | 0.19 | |

| 14 | sliding properties and friction coefficient | PLASTIC/STEEL(DRY) | 0.14 | |

| 15 | Shore hardness D | 64 | ||

| 16 | Charpy Notched Impact Strength | mJ/mm2 | No break | |

| 17 | Water absorption | Slight | ||

| 18 | Heat deflection temperature | °C | 85 | |